In the last chapter, I wrote about my concept for a sailor’s motorboat. However, I don’t know about you, but I have had enough of vapour boats lately, so let’s take another look at a breakthrough motorboat that really exists, with two on the water, and two in build, that ticks a lot of the sailor’s motorboat boxes.

And even more important than that, this is a boat that has just crossed the Pacific from New Zealand to Panama, the up-hill way—pretty impressive.

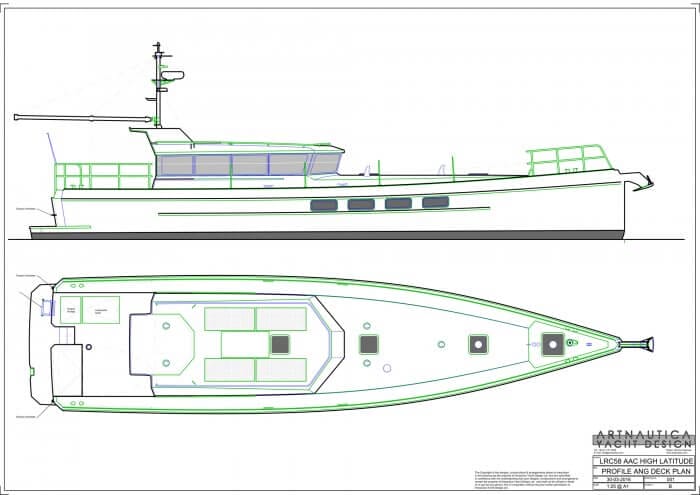

That boat is the Artnautica LRC 58, that we first wrote about when the prototype was just a pile of aluminum back in 2013.

Making it Happen

By the way, one of the things I love about the whole Artnautica project is that Dennis, the designer, made the boat real by selling his house for funding, rolling up his sleeves, and building the first one himself…talk about proving your point with a vengeance!

We Helped

And at least two of the four LRC 58s were ordered by owners who first heard about the concept here at Attainable Adventure Cruising. That, and our track record of inspiring several orders for Boréals, should give those of you interested in this concept some hope that it won’t go the sad way of the Adventure 40. Or better still, that we will eventually be part of making the Adventure 40 real.

I digress…but then what’s a little boasting between friends. Anyway, back to the Artnautica. Read on about our ideas for the Adventure Edition:

Hi John,

How about making the pilothouse watertight in the event of a window failure? Watertight doors can ensure no down flooding towards the galley and staterooms and the whole superstructure can be isolated with watertight glands for cables etc.

Hi Nikolas,

At first glance, that’s an attractive option, but there are issues:

Given all of the above, I would rather put money into making the windows and hatches bomb-proof—solutions exist in the commercial world, just look at lifeboats and pilotboats.

More on the problems and practicalities (or not) of watertight bulkheads here: https://www.morganscloud.com/2013/08/19/risk-management-and-watertight-bulkheads/

Hi John,

Even if it is not practical and cost efficient to make the pilothouse truly watertight: in the event of a broken window at the least internal watertight doors should be considered to minimize down flooding to what the bilge pumps can manage thus giving time for the crew for emergency repairs.

Already saving love the new version

Danny Blake

I’m very close to planning to buy this excellent craft in the next few years.

The 3rd hull has just been launched with No4 under construction. There is a growing interest and Dennis, the designer, has twin engine options under design.

Hi George,

Dennis did tell me some months ago that he would look at twins, so good to hear that’s happening.

John

As I understand, Dennis has 3 different engine and HP configurations with CPP to reduce drag and optimise fuel economy. In addition to the redundancy solution there is the level beaching characteristic also.

George

John

Yesterday we visited Rob Westermann, Artnuatica Europe, in Harlingen, Holland. We actually experienced a review/walk through his boat “BRITT” which is Hull No3. The design expresses confidence and the size is next to perfect. BRITT represents the original design with fixed bench construction on the stern and custom interior and instrumentation.

Dennis is near completion of the twin engine design for a customer. The developed High Latitude design with twin engine would seal it. We are now going through a requirement analysis for a twin engine model.

What was most fruitful from this meeting is that there are potential creative procurement options. This is a boat designer/builder with passion.

Naturally, your name came up. They are looking forward to your sea trial. What is the schedule for this sea trial?

Regards

George

Hi George,

Great to hear that things are going well with the Artnautica and that the twin version is in hand.

We have discussed me sea trialing the boat, but there is no schedule to do so. A key issue would be my time and travel costs which would need to be covered since there is no way that the associated revenue could justify AAC paying.

Also, I did suggest to Dennis and Rob that the Artnuatica community, including the boat yards that build them, might want to enter into a corporate membership with AAC to help support us, in the same way that Boreal has generously done for the last few years, and was turned down flat. This left me rather sore considering that the amount I suggested was modest, and the fact that all boats sold to date have been as a result of exposure here at AAC.

The point being that AAC is only just now struggling above the line of financial viability after 14 years of effort, so those who have leveraged what we do to sell several million dollars worth of motorboats need to think about how to help us keep our heads above the water.

All that said, on a personal basis, I would love to visit the boat and write about her, as well as continuing to contribute to the design evolution as I have in the past.

John

There has been considerable developments with Artnautical LRC58:

1. Twin engine option available designed and built.

2.Design for LRC65 complete

3.Electrical hybrid power option now under development.

I shall email the update.

Regards

Hi George,

Yes, I keep a rough eye on developments there.

What is a bit of a disappointment to me is that the whole line seems to be veering off into every bigger and more expensive boats that will burn more fuel and produce more carbon than the original. I’m also wondering if we can, or at least should, even entertain long distance offshore motorboats in the world we live in. That said, these boats are less of an impact than horribly inefficient short fat trawlers. In short, I’m struggling with the whole subject these days, particularly while sitting in a fuel thirsty RV.

Our Saga 43 also hunts at anchor, most likely due to the windage of double furled headsails. Adding a stern arch and bimini reduced the tendency significantly so if you can create some windage well aft it will help . How about a riding sail, maybe as part of your “get home” plan?

Roger

Hi Roger,

Great minds think alike. More on that in my upcoming post on get home options and stabilizing.

By the way, love the Saga 43. One of Perry’s best I think.

https://www.morganscloud.com/2009/11/01/saga-43-sailboat/

John,

I think Dennis’ LRC 58 is fantastic.

A few of suggestions.

A fully sealed cavity in the saloon house roof, of ample dimensions, might provide sufficient buoyancy in the event of a knockdown and prevent rollover if windows are breached – coupled with a bit of lead in a keel – see below.

The videos I’ve seen of the prototype show the boat to be lively with a fast roll (even the second built fully loaded version). Roll damping might be assisted by extending the propeller skeg forward to form a keel, filling, what seems to me, to be an unnatural void between the leading edge of the skeg and the forward sections of the hull. This would also push the centre of lateral resistance of the underwater body forward, perhaps mitigating the hunting at anchor. (A bit of lead in the keel might help with ultimate stability concerns and increase roll period.)

Another way to damp roll would be with retractable bilge boards.

Filling the auxiliary mast with water, when needed, should reduce roll frequency, at not too much cost to stability. (Not to be used in dangerous conditions.)

Is there any way you could ask Dennis to publish the vessel’s righting moment curve?

Hi Henry,

We will be covering roll damping and stability in a later post.

As to stability curve, as I say in the post, Dennis tells me that the boat will recover from a total inversion (and I believe that) so really a curve would not tell us anything very useful over and above that. Or to put it another way, worrying about a limit of positive stability is not really relevant when the boat does not have one.

Also, in thinking about inversion risk, it’s not generally a good plan with motorboats to come at it from a sailboat perspective (adding ballast). On a motorboat, particularly one like this one that will already recover from an inversion, adding ballast is pretty much a 100% negative approach since it will slow the boat down by adding wetted surface and in addition make her less comfortable by making the roll quicker.

On the idea of adding weight up high to damp roll, I think you are on to something, and we will be discussing that further in the next post on the subject.

John,

You said: “it’s not generally a good plan with motorboats to come at it from a sailboat perspective (adding ballast).”

I can’t see what the logic of this statement is. A power boat hull and sail boat hull are subject to the same laws of physics. And it depends on the amount of ballast we are talking about. It won’t be as much as required for a sail boat (which needs the ballast to balance the sail rig).

You said: “…adding ballast is pretty much a 100% negative approach since it ………make her less comfortable by making the roll quicker”

I am not sure this is correct. The roll period is a function of the gyradius and an inverse function of the square root of the metacentric height (GM). Increasing the gyradius increases the roll period, increasing the GM reduces the roll period. Ballast has an impact on both the gyradius and the GM. However, generally, I would think that heavy displacement boats have lower roll periods than light displacement boats. We have to be very careful what we say here.

You said: “…adding ballast is pretty much a 100% negative approach since it will slow the boat down by adding wetted surface…”

It would also increase wave making resistance. So on both counts, fuel consumption will go up. The question is, is the LRC58 safe enough in an ocean seaway? It seems to me that ultimate stability is a big factor in this. As in all these things it’s all a compromise, as you well know. I would rather give up some fuel consumption for increased ultimate stability. You spent a good deal of your discussion dealing with roll over risk or the risk of a wave breaching the integrity of the windows. Ballast may be a part of adding protection against this. The question is, how much ballast would be required? What affect would that have on fuel consumption and are you prepared to wear the higher consumption as a trade off for safety. It seems to me you are concerned about “oceanizing” the LRC58 and considering ballast might be a factor in this. Being able to recover from a knockdown is fine, as long as the windows aren’t breached. You have mentioned beefing up the windows. This adds considerable weight high up which will impact ultimate stability. Some ballast might be required to balance this.

You said: “On the idea of adding weight up high to damp roll…”

It doesn’t damp the roll. It increases the roll period and makes the boat less jerky. To damp the roll, you need appendages which provide resistance to roll (as in extending the keel or adding bilge plates as I mentioned above) or hull shape. I would think the LRC58’s flat hull shape with chine tends to damp roll.

Please don’t think I am pretending I am an expert in these matters, far from it. The LRC58 is a fine design, but is it oceanworthy? I am merely trying to provide food for thought – perhaps the LRC58 is fine as she is as far as crossing oceans go. I don’t really know. (But watching her videos does suggest she has fast motions.)

Interested in your comments.

“However, generally, I would think that heavy displacement boats have lower roll periods than light displacement boats. ”

I should have said have LONGER roll periods.

Hi Henry,

I’m pretty comfortable with the accuracy of my original comment on the matter, and don’t see a lot of benefit in getting into a long discussion, particularly since this would take a lot of time away from what I can do well: applying my considerable offshore experience to looking at ways to make the boat safer, like ditching the cockpit or setting up for A JDS—just playing to me strengths here.

And, I’m also pretty comfortable that the LRC 58 it seaworthy, although, as I said in the post, I would not commit to that until I have had a chance to take one offshore in some waves and wind.

As to roll period etc, I will be covering that in a future post (which I need to get on with writing).

John,

I am also wondering why the propeller and rudder are so far forward?

Wouldn’t they be better as far aft as possible. This would also straighten the hull lines as they run aft.

Hi Henry,

I really don’t know. My thinking on such things is that it’s better to pick a design I like and then leave such things to the designer. I’m just not qualified to start second guessing the position of underwater appendages.

That said, I guess if I really liked a design, but was not totally sure about it, before building a boat I would hire a qualified naval architect to review it.

Hi Henry,

I kept the propeller and rudder forward in order to ensure they would stay fully submerged in steep following waves. They are also well protected in a med mooring situation with the stern against the dock. What makes them seem a bit further forward than necessary is that originally the design did not have the swim platform extension as part of the hull.

Dennis,

“I kept the propeller and rudder forward in order to ensure they would stay fully submerged in steep following waves.”

Have you ever thought of using stern water ballast in following seas. This would lift the bow and reduce broaching tendencies. It would also bury the rudder and propeller more deeply.

Hi Dennis,

Thanks for catching that one. Way above my naval architecture pay grade.

Will there be a post on cost?

Jim

Hi Jim,

I’m thinking about a post on the whole affordability issue, particularly for aging sailors with some equity in a sailboat, focused on cost of ownership between changing from a sailboat and retiring from the sea altogether as we age. Also, I’m wondering if the ARC 58, or a boat like here, could be made more affordable by building several at once. Price will be part of that post.

Just an FYI I was influenced by Colin’s articles about his Alubat Ovni 435, to purchase a Alubat 395 this year. So the influence of ACC grows….

Hi Richard,

That’s nice to hear, thank you. Wishing you some great voyages in your new boat. Always great to hear of another person getting out there in a good boat.

Great post and interesting boat. Regarding the hunting at anchor issues, I often wonder why modern boats are still usually anchored from the bow when they lie so much better from the stern. There would be issues with stern anchoring to solve such as overhang to keep the anchor from hitting the boat, but there are solutions for that. Anchoring from the stern, with a primary anchor setup designed into the stern, would keep the work near the helm for better communication and possible one-person anchoring, keep the weight of the anchor system out of the bow, allow an anchor bridle system to attached to bomb-proof chain plates on the stern, and eliminate hunting at anchor. I’ve seen one boat do it and it seemed to work great. Any ideas why more builders don’t experiment with stern-mounted primary anchoring systems?

Hi David,

Yes, I think there’s a lot of potential in that idea. There are issues with most boats that would, I think, require a complete redesign, or at least substantial modification. The most notable would be moving all the weight of anchor and chain from bow to stern. Other issues to solve are wave slap noise on the stern and rain driving into the cabin every time one opens the hatch.

That said, there is no question in my mind that on a fundamentals basis you are right, many modern designs would benefit from a complete rethink in this area.

I’ve thought of this also. It seems to keep driving my thoughts towards double enders….

Hi Daryl,

Double enders have their own set of issues so I’m not sure I would take those on just to be able to anchor by the stern.

What about superduplex 2507 for material.

New stainless steel.

One company in Sweden is using it.

Hi Peter,

I don’t think this hull form would work well in steel of any type. Aluminium has a substantially higher strength to weight ratio than any steel, so the boat would be a lot heavier in steel to achieve the same strength. That in turn would require a complete redesign.

Also, although I don’t know about superduplex, generally stainless steels are even less strong for their weight than non-stainless.

I took a quick look at the web site and the big claim seems to be “maintenance free boat” but the same is true of unpainted aluminium, so I can’t really see an advantage.

I also note that they are claiming new construction techniques that allow them to make the hull plate “extremely thin”. Perhaps this is so, but, while some successful boats have been built of stainless, the history is, as I understand it, not generally good, whereas aluminium construction like that used in the Artnautica has a long and successful history: https://www.morganscloud.com/2012/07/01/one-tough-old-aluminum-boat/

So, in summary, I can’t see the benefit it leaving a well proven material for a new an unproven one.

Point taken, just that it looks to be avery nice material and I know that Sandvik don’t make something half hearted.

Merry Christmas from Sweden

Hi John,

A few remarks.

Helm seat: I will have no helm seat at all. Just an inside helm with a steering wheel which I will primarily use when docking. On my previous boat, I only used the inside helm position when sailing thru canals like the Nord-Ost canal to Kiel Germany (100 km) and of course when sailing (busy) inland waterways. Two helm seats surely is a bit over the top.

Outside control station: Hmm. I opted to not have a second control station. The only drawback is that if I am alone I have to go out to the cockpit, which obviously takes some extra time. This is especially important when negotiating locks. We’ll see how it works out. As a side remark I also will install a mooring winch on starboard aft near the bollards to ease docking when the wind blows over Beaufort 6 (24 kn).

Windows: Heat *) and strength. We will have double glazing throughout except for the hatches so heat is less of a problem. What is on the table right now it what thickness the outer glass should have (it is now to be constructed as 12mm outside, a air gap of 6mm and 6mm inside). In Europe we have to comply with the CE certification (Category A — Ocean) so the glass supplier as a minimum must follow suit. But having said that I fully agree with your statement that storm covers must be part of the inventory.

*) Heat in general when an aluminium boat is not painted. We will paint (anti-slip) all the horizontal pieces of the boat. Unpainted aluminium can become very hot in the summer so the yard tells me. In Europe we will not need air conditioning. But if one is going to sail in the Mediterranean or in the tropics some sort of (perhaps even active) ventilation must be installed.

Robertus, owner-to-be of LRC58 hull #3

Hi Rob,

Thanks very much for the fill on what you are doing with your boat.

On the thoughts about second helm: I posit that wireless remotes have evolved to the point that only one (inside?) steering station is needed. Perhaps (several) mountings for MFDs would be useful.

Hi Daryl,

Yes, I have read about these wireless boxes. That said, it would take a lot to convince me to trust one, particularly on a metal boat where the signal could get blocked.

They are well proven in industrial/construction uses. Most newer travel lifts, cement pumpers ect. I would certainly test the living daylights out of it before trusting it in close quarters.

I was (pleasantly) surprised to find that my B&G plotter could be “seen” by my Android tablet using B&G’s “Link” (essentially remote display and function) outside of my steel-sided pilothouse. Would I rely on this at the outside helm? No, I wouldn’t: I would have an outside plotter on deck (there’s a second helm station there). Would I find it helpful, say, when displaying the forward-looking sonar screen when anchoring? Sure, if it works consistently.

My Vesper XB-8000, like the plotter, seems to find wireless through the steel sides of the pilothouse and GPS through the aluminum roof easier than I would have thought. Just another data point.

The above comment shows that even a low-production, specialized vessel such as the one under discussion can require considerable modification and customization to be “fitter” for purpose according to the needs of the owners in the areas they wish to operate.

Boats are therefore akin to the first 25 years of car production, during which “coachbuilders” would essentially complete hand-assembled chassis. Production boats are more like Model Ts; you can have exactly what is presented at time of purchase, and any modifications are between you and your wallet.

John,

When do you plan the second part of this one?

Regards

Giles

Hi Giles,

I’m not sure, it’s definitely on the list, but not yet specifically scheduled.

Dennis has a new website:

http://www.artnautica.eu/

His Facebook page says hull #3 is nearing completion in the Netherlands.

Hi Henry,

Yes, the owner of the boat being built in Europe, who is also behind the web site, has been sending me regular updates on the build with photos. Looks like a really nice job.

Hi John,

As to motion comfort and stability, what would happen if you had stabiliser type fins added to the hull. Kind of like bilge keels (would be handy for drying out in big tidal areas). Would their aqua-dynamic effect (foils/lift?) tend to hold the boats roll angle (resisting that flat aft sections desire to follow wave shape), reducing roll? This would be way cheaper than stabilisers (though not quite as effective), with no required maintenance. Maybe have Matt chime in also with some engineer-foo…

Though I’m not a long range offshore cruiser… (I can dream can’t I) I have a 30′ Grampian sloop (5.5-6 ton loaded displacement. Coastal and ICW)

And a 35′ ChrisCraft Comander-sport cruiser ( 10 ton dis.) very efficient hull at 7+ knots (burning about 2 gph on one engine). Almost no wake at all. Though it is one of those short, fat gas hogs when up on plane. We won’t talk about (or achieve) that gph.lol. I like 7kts.?

Hi Robin,

Bilge keels do provide some stabilization, but not near as much as dynamic solutions. Also, I don’t think bilge keels would work well with the the Artnautica hull form. As I understand it, they tend to work better on slack bilged deeper boats. If memory serves, Michael Kasten has a good article on his site explaining this.

If I were looking at an Artnautica and wanted stabilization I would look at paravanes. I gather one of the boats has been so fitted and it has worked well.

As to your Commander, planing hulls are not generally efficient at displacement speeds, and that would seem to be the case here in that at the same fuel burn our Morgan’s Cloud is doing 7.9 knots and moving 25 tons. And that’s dragging a mast and keel that a pure motorboat would not need. The other problem with running a planing boat slowly is glaze up of the engines.

Thanks for the reply.

I’m really liking the LRC 58. I’D want he adventure version 2.00, with the version 1.00 interior with wet locker, oversized running gear, dual hydraulics with dual auto pilots (ala FPB). Cabin top would get 6 solar panels (with a corresponding 1000-1200 AH battery bank), a vent and 2 dorades at the front edge, and 2 dorades at the aft end of the top (the dorades should help with overcoming the solar gain of the windows) . Also some UV/IR blocking window coatings. Some tint on the sides, none on the front.

Sounds like maybe some paravanes too. Also one of the small sails for the boom to stop hunting at anchor. Cool stuff. ?

Had the pleasure of visiting Britt, build nr. 3, last week. Today we went for a short off-shore cruise. Delightful boat!

Glen Farr

I love the am loving the Artnautica design, and all of this commentary . . . until we get to “adios cockpit”. That is such a wonderful section of the boat at anchor or underway in calmer conditions. So, why couldn’t you keep the cockpit and to prevent the possibility of getting pooped by having a cockpit well cover. It could be a rigid cover that gets dogged down before heading off shore, or have a super rugged fabric-like cover that is attached like those swimming pool covers that people walk on. With the later, perhaps the cockpit cover is fitted over the cockpit well and also over the dinghy which would also be stored in the cockpit. I’m very novice here, so after some pitfalls are brought to my attention, I’ll take a junior varsity atta-boy for creativity ; – ). Also, although it would be more of a coastal cruiser, Phil Lambert who built the Outbound 46’s, is undertaking the Rangeboat 46 ( Rangeboat.com ). While not intended as a bluewater/offshore boat, it checks a lot of the same boxes as the ArtNautica 58. Knowing Phil, it will be a great boat.

Last, I saw that ArtNautica #3 “Britt” was for sale in Europe. Anyone know why the owner wanted to sell?

Hi Glen,

I agree, getting rid of the cockpit has drawbacks. But keep in mind that this idea was for an Adventure edition intended to go to more hazardous seas. And having cruised those places for many years that would be my recommendation. A big sea could easily demolish any sort of cover. Its very hard to fully appreciate the power of a wave breaking aboard, usually in a partial broach, until we have seen it happen. All that said, for a coastal boat, sure, the cockpit is great. You can read. more about my thoughts on down-flood risk here: https://www.morganscloud.com/2020/12/28/safe-and-seamanlike-cockpits/

And yes, I have bee n chatting with Phil about his new boat and he is very clear that it’s not an offshore boat.